Treatment Technology

The Buildings Taking Shape Now

1 Headworks building

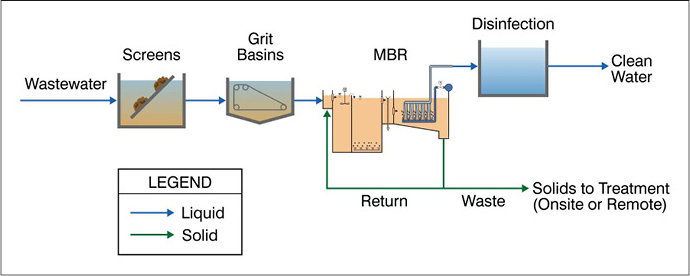

- Wastewater will enter the facility through pipes under SE City Beach St and pass through an initial screen, which removes heavy material.

- Next, wastewater enters the vortex grit chamber and is swirled around, which helps grit (similar to sand) settle to the bottom of the chamber for easier removal.

- Wastewater passes through a fine screen, which filters out any sediment that passed through the initial coarse screen and the vortex grit chamber.

2 Aeration basins/Waste activated sludge storage

Air is mixed with the wastewater, stimulating the growth of microorganisms that consume part of the waste. The wastewater sits in large tanks, called aeration basins, for three to six hours.

3 Secondary treatment building

Wastewater passes through the membrane bioreactor (MBR) to separate microscopic solids from liquids.

4 UV treatment

Liquid gets its tan on and flows through a pipe with UV lamps throughout the interior. The UV light kills microorganisms in the liquid by damaging their DNA. The treated water travels through the outfall pipe into Oak Harbor Bay.

5 Solids building

After separating from liquid wastewater via the membrane bioreactor (MBR) in the secondary treatment building, solid waste is dried in a solids dryer. The waste travels across a belt while hot air flows over it, drying the waste as it travels through the unit.

6 Maintenance building

Equipment stored here helps make sure the machinery in the new Clean Water Facility stays in tip-top shape.

7 Odor control

Air pumped from other buildings is “scrubbed” by biological materials that absorb odors. Next, air is “polished” by activated carbon (fancy charcoal) to absorb any remaining odors. Treated air is released.

8 Aeration blower building

Blowers pump air into the aeration basins to stimulate the waste-eating microorganisms.

9 Electrical building

Treating the City’s wastewater requires consistent electric power. Equipment will monitor and maintain the facility’s electricity.

10 Emergency generator area

Wastewater doesn’t stop flowing when the power’s out! This building’s name says it all - the emergency generator will provide back-up and emergency support in case of an outage.

11 Administration building

Keeping Oak Harbor’s wastewater flowing takes a lot of work! Facility staff will monitor quality in the lab and maintain system functions via a control network.